Portable Devices & Accessories

ELOTEST M3

The ELOTEST M3 offers a large size LCD display with stunning definition and brightness. When multiple inspectors have to review images for evaluation or precise handling of the probe does not allow capability of holding the instrument, the M3 will be the instrument of choice based on the large display and intuitiveness of the parameter adjustments.

Elotest M2 V3

The ELOTEST M2 is a universal one-hand test instrument for surfaces, bore holes and hidden structures. In addition, it measures the conductivity and layer thickness of all materials. The ELOTEST M2 features a DUAL-frequency inspection with mix and covers the entire frequency range from 10Hz to 12MHz

ELOTEST B300

Rotor EC15

Hand-held rotors and rotating probes

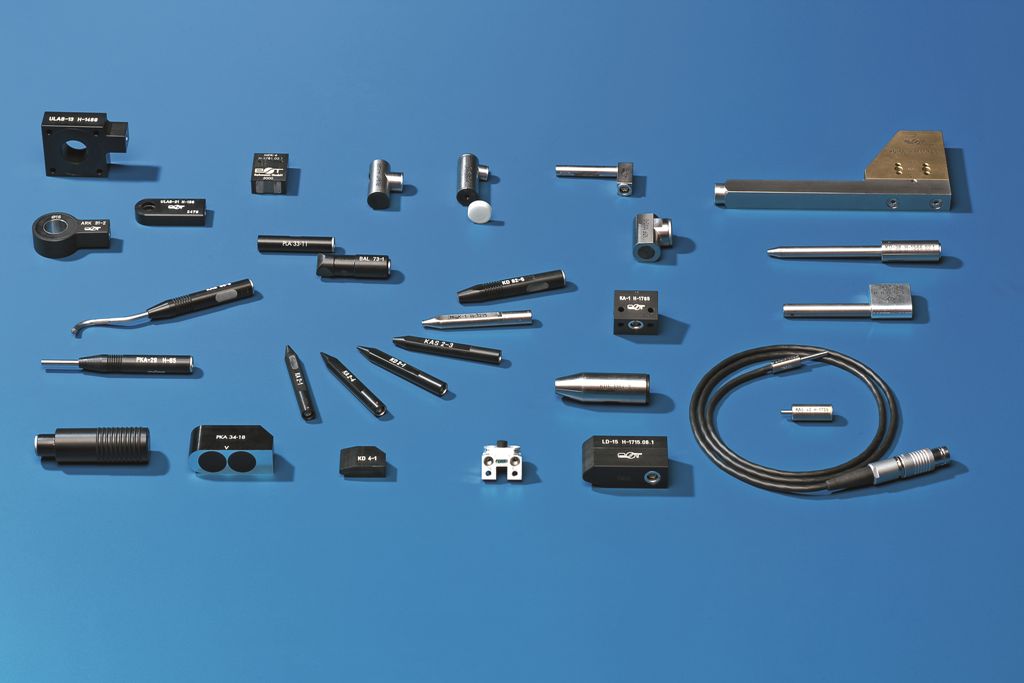

Sensors:

There are national and international standards as well as guidelines by manufacturers and operators that specify minimum requirements for inspection systems used for many applications. We are able to quickly and flexibly respond to the customers’ requirements with a multitude of probe types. If a special probe has to be developed for a particular inspection we can fall back on a wealth of know-how.

Reference Standards